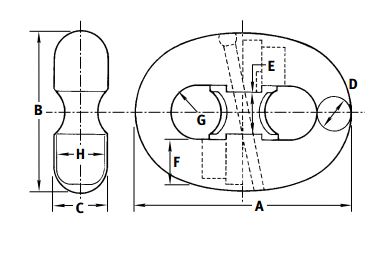

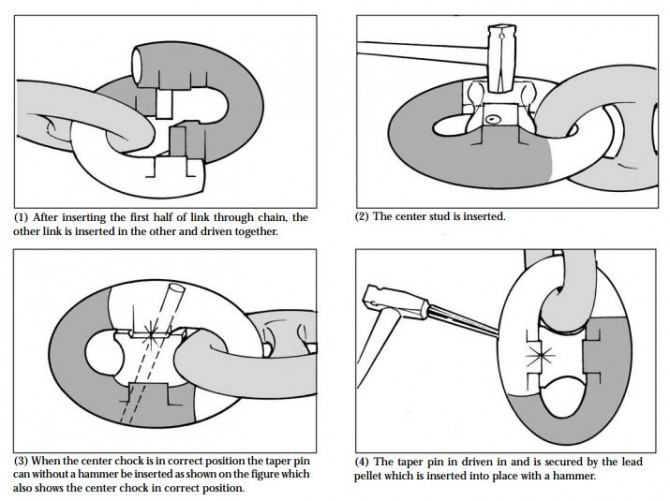

The Kenter-type joining link contains three parts plus taper pin and lead plug. The two main halves have numbers to be matched and arrows to be lined upfor ease of assembly with the third piece (stud). The two main parts are attached to the ends of the chainin a vertical position and then fitted together (1), and the stud is then slid into place (2), which locksthe link. The stud is secured by hammering a taperedpin into the hole drilled diagonally (3) through allthree parts of the joining link. This hole is tapered, and when the pin is driven home, a small conical recess (called the “dovetail chamber”) is left clearabove its head. A lead pellet is hammered broad end first into this chamber (4) so as to fill it completely and thereby keep the pin in place.

Precaution must be used to prevent flat, small pieces of lead from flying off the joining link into the face or eyes. Prior to assembly, the internal mating surfaces should be coated with a molybdenum disulphide grease (MIL-G-23549) or an equivalent lithium based grease. When assembling and before inserting the new lead, any remaining lead must be reamed out. When dissembling, the locking pin is driven out with a “drift”. To part the link, a top swage (shaped to the curvature of the link) must always be used between the hammer and link so as to avoid damaging the machined surfaces.